After-Sales Service

1. We design, engineer and manufacture and customized the extrusion line.

2. Choosing the right solution: In plastics manufacturing, process is everything. We carefully evaluate each project's requirements, weigh the options and recommend the best solution for the client.

3. Training & Development: we offer extensive start-up assistance, comprehensive training. As well as Engineers for training and installation at our client’s factory

4. Support: We support the client in all the stages of the project life cycle, as well as the constant spare parts supply in a time efficient manner.

APPLICATION

The pp hollow cross section plate is light and high strength ,moistureproof good environmental protection and refabrication perfor mance.

Can be processed into the reusable

container,packing case,clapboard ,backing plate ,and culet.

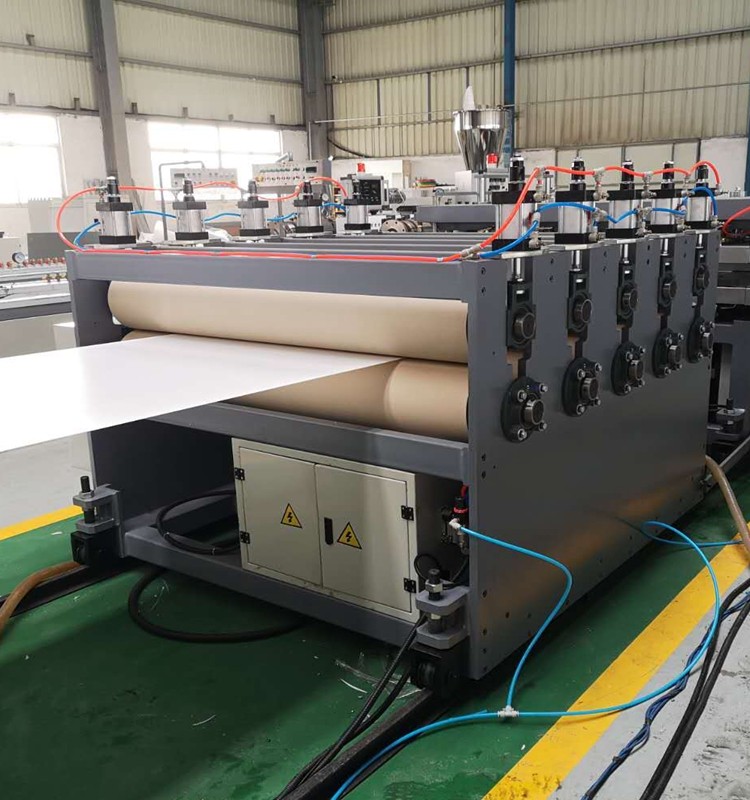

For PP/PE hollow cross section plate extrusion line:

|

Extruder model |

120 |

100 |

|

Product width |

2100mm |

1220mm |

|

Product thickness |

2-8mm |

2-8mm |

|

Main motor power |

132kw |

110kw |

|

Capacity(Max.) |

350kg/h |

200kg/h |