Comparing of canton packing material and PP hollow sheet material

1, Paper - paper fear of water, fear of tide, perishable, can not guarantee the quality of the product transport, there may be increased costs, so most of the cartons, cartons, cardboard and other paper products can only be used once.

2, PP hollow sheet related products can be flexibly produced, compared to the expensive plastic injection box, PP hollow sheet box cheaper many, customized according to customer size, thickness, toughness, hardness, printing, etc.

3, Traditional cartons will be broken after several times of using, the PP hollow sheet crates life is about 20 times of the carton material, or even longer, it can reduce the using cost greatly.

4, And the PP hollow sheet products are non-toxic, pollution-free, environmental protection, waterproof, moisture-proof, shock absorption and other characteristics, compared with traditional cardboard, wood, easy to use, easy to store, can be reused, long life, but also recycling, Higher social and economic value.

Main technical specification |

||

| Extruder Model | φ135/38,φ50/30 | φ110/38,φ45/30 |

| Products width | 2100mm | 1300mm |

| Products thickness | 2-10mm | 2-10mm |

| Main motor power | 185kw/22kw | 132kw/22kw |

| Designed capacity | 450-550kg/h | 250-350kg/h |

MACHINE FEATURES

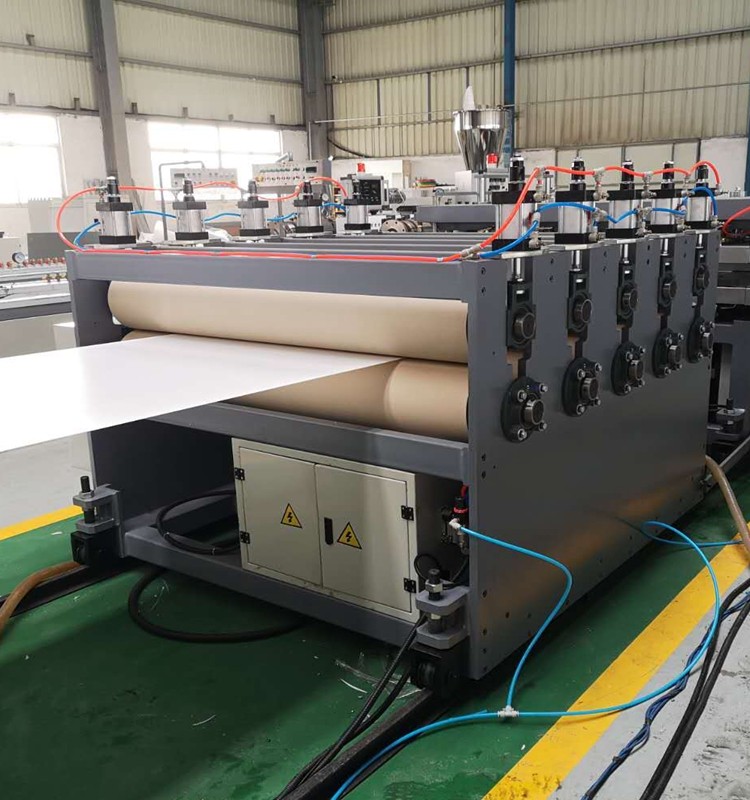

1. The softness of pull rolls could be customized on request to extend its stretch.

2. The air capacity of hollow sheet and low pressure could be adjusted and controlled slightly, which is easily to be controlled than any other brand extrusion lines.

3. Unique T-Die is specially designed for PP hollow sheet. The thickness of hollow sheet could be from 2mm to 10 mm with twin-wall. The ribbed between walls could be rectangular and diagonal shape.

4. Anti-UV co-extrusion layer could be one sided or two sided, outer surfaces could be sandy or glossy according to configuration requirement.

High percentage of recycled flakes could be mixed with the virgin materials.